What to Expect During a Visit to a Brush Machine Factory

What to Expect During a Visit to a Brush Machine Factory

Blog Article

Visiting a brush machine factory can be an enlightening experience, offering a glimpse into the intricate world of manufacturing. One such establishment that stands out in this industry is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With an impressive 37 years of production experience, this company has garnered a reputation for excellence in the design and creation of advanced 2-5 axis machines. As you step into their facility, you will witness the convergence of innovation and skill that has been cultivated over nearly four decades.

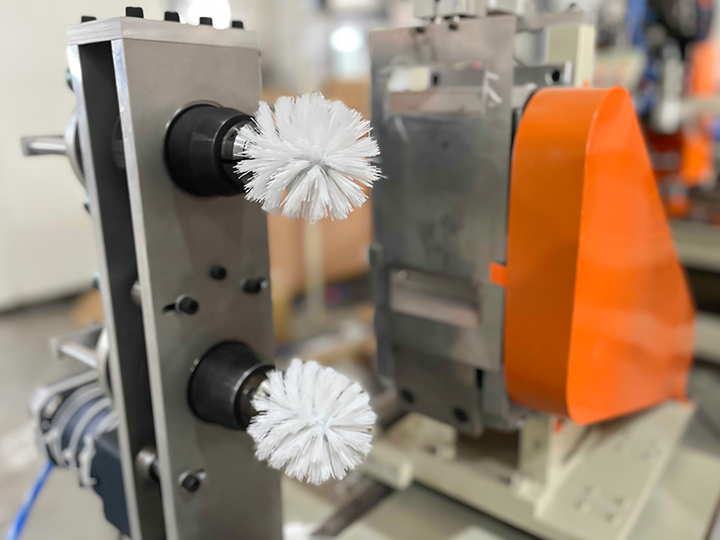

As you navigate through the factory, expect to see a range of machinery in action, each piece playing a vital role in the brush-making process. From the initial stages of production to the final assembly, every step is carefully executed by experienced professionals who are passionate about their craft. This visit promises not only an understanding of the technical specifications involved but also an appreciation for the dedication and expertise that goes into producing high-quality brush machines.

Meixin Custom Brush Manufacturing

Overview of Jiangmen Meixin

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands out as a leading player in the brush machine industry. With 37 years of dedicated experience, the company has honed its expertise in the production of high-quality 2-5 axis machines. This extensive background allows them to deliver precision-engineered products tailored for various manufacturing needs.

The firm is committed to innovation and advancement, continually investing in technology and design improvements. This focus on research and development has enabled Jiangmen Meixin to stay ahead of market trends and meet the evolving demands of customers across different sectors. Their state-of-the-art facilities are equipped with modern machinery that ensures efficiency in production and exceptional product quality.

In addition to their technical capabilities, Jiangmen Meixin prides itself on providing outstanding customer service and support. The company understands that building strong relationships with clients is crucial for long-term success. By offering expert guidance and assistance throughout the purchasing process, they ensure a seamless experience for customers seeking reliable brush-making solutions.

Types of Brush Making Machines

Brush making machines come in various types, each designed to cater to specific manufacturing needs. One common type is the single-axis machine, which is suitable for simpler brush designs and is often easier to operate. These machines provide a cost-effective solution for small-scale production and are ideal for manufacturers who are just beginning to explore the brush-making industry.

On the other hand, multi-axis machines, such as the 2-5 axis models produced by Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., offer greater flexibility and precision. These machines can create complex brush shapes and designs, allowing for higher production output and reduced manual labor. With advanced technology, these multi-axis machines significantly enhance the efficiency of brush manufacturing processes.

Another important category is the automated brush making machines, which often integrate robotics for tasks such as loading and unloading materials. Automation streamlines production and minimizes the potential for human error, resulting in a more consistent product. These machines are particularly beneficial for larger manufacturers looking to scale their operations and meet growing demand for a variety of brush types.

Production Process Insights

Visiting a brush machine factory like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. offers a fascinating glimpse into the intricate processes involved in brush production. With 37 years of experience, the factory showcases advanced technology and expertise in manufacturing 2-5 axis machines. The production process begins with the careful selection of raw materials, ensuring that only the highest quality fibers and materials are used to create durable and efficient brush products.

Once the materials are selected, the manufacturing process involves several stages, including cutting, shaping, and assembling. Each step is carried out using precision machinery that automates many tasks, enhancing efficiency and consistency. Jiangmen Meixin employs skilled technicians to monitor the machines and make real-time adjustments, ensuring that the final products meet stringent quality standards. Visitors often appreciate the seamless blend of technology and human oversight that characterizes the factory's operations.

Finally, quality control remains a paramount aspect throughout the production process. Each batch of brushes undergoes rigorous testing to guarantee functionality and durability. The insights gained during this stage highlight Jiangmen Meixin's commitment to excellence, as they aim to maintain a reputation for delivering high-quality brush machines to clients worldwide. Observing this meticulous attention to detail reinforces the importance of quality in the manufacturing industry.

Quality Assurance Measures

At Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., quality assurance is a fundamental part of the manufacturing process. With 37 years of experience, the company has developed a comprehensive quality control system that is integrated at every stage of production. This system ensures that each brush making machine meets rigorous industry standards and specifications before leaving the factory.

The quality assurance team conducts regular inspections and tests on both raw materials and finished products. These inspections help identify any potential issues early in the manufacturing process, allowing for timely adjustments and corrections. This proactive approach to quality management not only enhances the reliability of the machines but also boosts customer confidence in the products offered.

Furthermore, ongoing training and development for the staff play a crucial role in maintaining high-quality standards. Employees are equipped with the skills and knowledge necessary to identify defects and implement quality improvements. By fostering a culture of quality within the organization, Jiangmen Meixin ensures that the machines produced are not only efficient but also durable and long-lasting, meeting the evolving needs of their clients in the brush manufacturing industry.

Visiting the Factory: What to Expect

When you visit Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., you can expect a comprehensive overview of their advanced production processes. As a professional company specializing in the creation of 2-5 axis machines with 37 years of expertise, the factory tour offers insights into the cutting-edge technology and skilled craftsmanship that define their operations. Visitors will likely witness the intricate assembly lines where precision meets innovation, revealing how the machines are designed and produced to meet industry standards.

Expect to interact with knowledgeable staff who are eager to share their wealth of information about the brush machine manufacturing process. From the sourcing of materials to the final quality checks, each step is essential to ensuring that the machines function efficiently and effectively. This interaction not only provides a deeper understanding of the machinery but also highlights the company’s commitment to excellence and customer satisfaction.

As you conclude your visit, you will have the opportunity to see demonstrations of the machines in action. This hands-on experience will give you a clearer picture of their capabilities and applications in various industries. Understanding how Jiangmen Meixin’s machines can enhance productivity and precision in brush manufacturing will provide valuable insights for potential customers and partners looking to invest in high-quality equipment.

Report this page